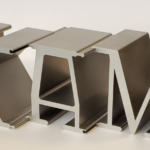

EDM

Wire EDM Capability

KAM’s specialty is EDM, which is used for high precision and demanding applications. EDM takes more time but the results are well worth it for tight tolerances, intricate pieces or working with hardened steel or exotic alloys. EDM works on the principal of highly controlled erosion by electrical discharges. Other EDM benefits are an excellent surface finish and a minimal heat-affected zone. At KAM we cover the three categories of EDM:

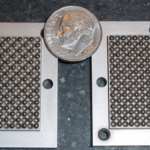

At KAM we cover the three categories of EDM:Wire — uses a super fine brass wire somewhat like a band saw. The wire must pass entirely through the workpiece, making a two-dimensional cut in a three-dimensional part.

4 Mitsubishi Wire EDM Machines- High taper 4-axis cutting

- Cuts any metal up to 12.200″ Tall

- Accuracy of + /- 0.0001″

- Max wire cut size (WxDxH): 23.500″ x 15.600″ x 12.2″

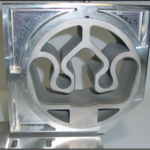

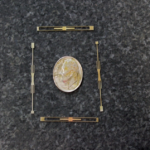

Die Sinker — used to create complex cavity shapes. A graphite electrode is machined to form a “positive” of the desired cavity. This electrode is plunged into a workpiece (submerged in dialetric fluid), causing sparking over its surface that erodes the workpiece into the desired form.

1 Sinker EDM Machines- Programmable C-axis

- 7 position tool changer

- Max work piece 37″x22″x16″

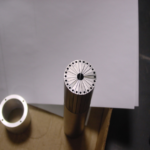

Hole Drilling “Hole Popper” — creates accurate and precise holes using a rotating conductive tube.

Small hole EDM- 0.008″ Minimum hole diameter

- Max work piece 17.7″x11.8″x11.8″